A craft or microbrewery is a labor of love. Just as with the mash tun and fermentation vessels, owners want the best brewery drain for their brewhouse.

If you are a brewer – or even a contractor planning a brewery construction – you understand that big decisions are made at every stage of construction.

One of those decisions is the type of trench drain you should use in the brewery.

So, what is the best brewery drain?

“Best” is a factor of longevity, which is a factor of materials cost. Stop thinking about the best brewery drain and start asking yourself what would be perfect for your brewery.

After that, the answer is simple. The perfect brewery drain is the trench drain system that meets all of your project requirements.

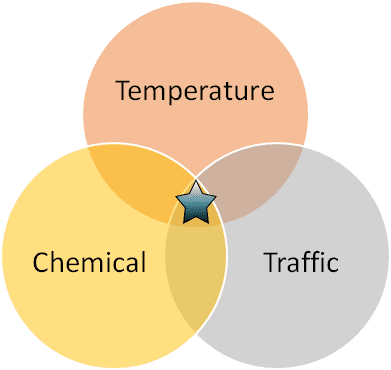

There is no “best brewery drain,” but you do want a floor drain that wins the brewery trifecta on a reasonable budget:

- Heat/Temperature

- Corrosion

- Traffic/Load Bearing

A Drain that can take the heat

While temperatures may vary, the brewing process gets hot. One place guaranteed to catch that heat is the floor drains, so new brewers need to be prepared.

The temperature of the water/cleaning solutions is always a concern when designing a drain. If hot water is poured directly into the drain, there is little time for the water to lose heat.

But if the drain is located in the middle of the room and tank water is allowed to run over the concrete floor, most of the heat dissipates into the concrete and air before hitting the drain.

When considering the thermal capabilities of a trench drain, I think the largest problem experienced is not with the deterioration of the channel, but of the thermal expansion of the channel.

Plastics (HDPE and PP) have a high thermal expansion compared to the concrete that surrounds the channel. Polymer concrete, SMC/GRP and stainless steel are close to the same thermal expansion as is concrete. Because of this, there is little or no stresses due to differential expansion during a hot water cleaning event.

A Drain with Chemistry

Between the brewing process and the cleaning, that hot water will have varying levels acids and bases mixed in.

Luckily, most trench drain systems have an inherent resistance to corrosion. Stainless drains are famous for it. Polymer concretes are bound with resin (polyester or vinyl ester), which protects the aggregate from acids. Plastics and SMC/GRP materials are also highly chemical-resistant.

The only drain you should 100 percent definitely not use is a poured-in-place trench drain that uses regular ol’ Portland cement. My gripes against this are numerous, but here are two simple reasons:

- Your drain has no protection against corrosion without surface treatment, and

- If treated, your drain has only surface treatment that will scrape or weather off

The actual data on chemical resistance depends on heat and chemical concentration. So it helps to have an idea of what you’ll be putting in your drain and at what temperatures.

A Drain you can build on

My highest recommendation is to plan for the future, not the present.

So your operation is small – foot traffic only, you say. Ask yourself whether the facility has room to expand – and how you want to do it. The foot traffic rated trench drain may end up handling pallet jack or forklifts. It is much easier to plan ahead than to replace later.

| Planning for Traffic | |

|---|---|

| Anticipated Traffic | DIN/EN 1433 Load Ratings |

| Foot Traffic | Class A-B |

| Pallet Jack | Class C |

| Forklift | Class E |

Most brewery drains can handle pallet jacks without extra reinforcing, but almost all need frames once forklifts come into play.

Only custom stainless drains and specialty stainless bar grating can withstand forklift traffic sans frame. And remember what I said about longevity and material cost? It holds true.