Fiberglass Grating

As the price of stainless steel increases, fiberglass is filling the gap. Fiberglass is a component that has been found to be very useful in many trench drain applications. This strong, lightweight material is easily fabricated into grating for standard and custom drain applications. It’s chemical and corrosion resistance puts it in a class with stainless steel, while being more cost effective. Think of using fiberglass grating in kennels, kitchens or drains exposed to salt water or coastal environments.

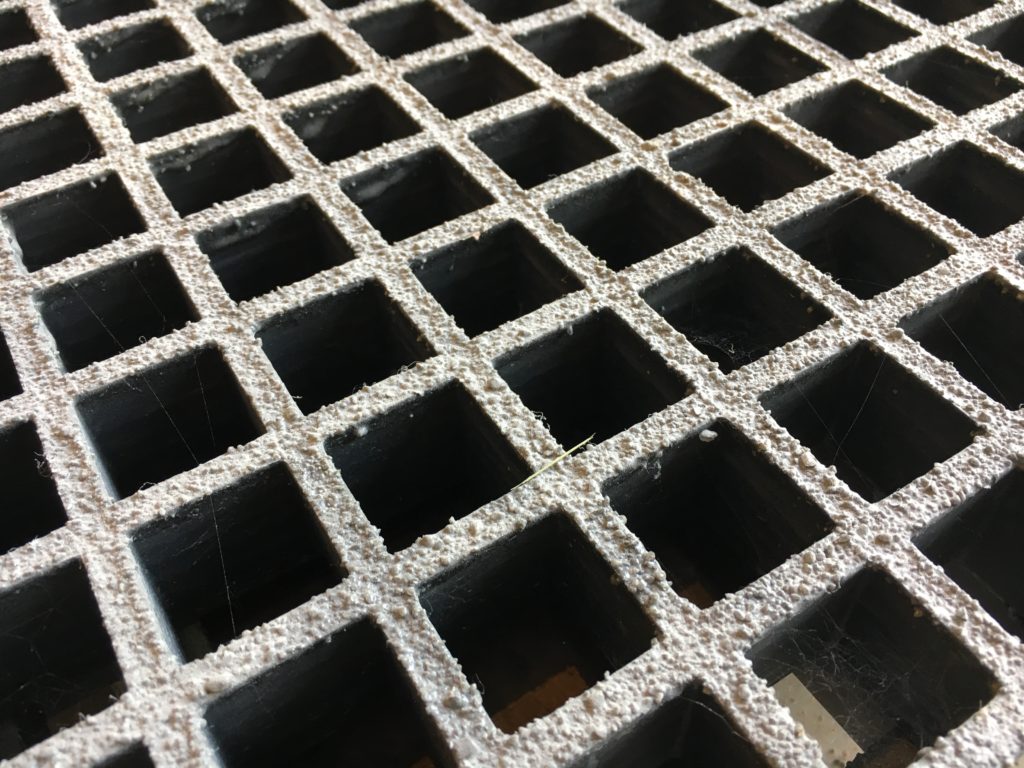

Molded Fiberglass Grates

The molded fiberglass forming method is usually used for making mesh grating and involves a jig that is the size of the desired final product. A fiberglass thread is arranged and stretched within the mesh shaped wall recesses of the jig before adding a polymer bonding material. If desired, an abrasive sand-sized material can be applied to the surface at this time to form a non-slip surface. This type of molded fiberglass is most often used for pedestrian and some light traffic applications.

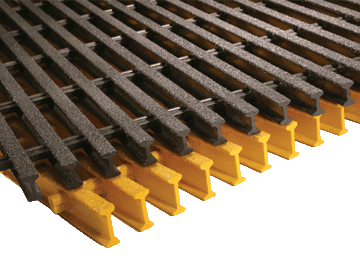

Pultruded Fiberglass Trench Grates

Fiberglass grating made from the “pultrusion” method (pulling + extrusion) is strong enough to be used in structural applications. This forming method involves pulling fiberglass reinforcing through an extrusion die, which simultaneously applies binders, heat and protective coatings to the bar or rod-shaped component. When this method is used for making I-beams, it can rival the functionality of conventional steel.

Pultruded bar grating has potential to replace cast iron grating of the same dimension, though not at the same price. While the grate is strong and the cross members help to concentrate that strength, if a vehicle’s wheels turn too abruptly while on the grating the cross members can be weakened and compromise the grate’s overall durability.

Micro-mesh

Micro-mesh can be made with or without a slip resistant coating. It is corrosion resistant, lightweight, nonconductive, and nonmagnetic. These grates have an open area of 44.4% and are ADA approved. Fiberglass Micro Mesh grating is now available in 4′ or 8′ kits, which include grates, locking devices, and frame rails. Custom lengths are also available upon request.

Square Mesh Grating

Molded mesh grating is one of the most common types of fiberglass grating. Thicknesses vary from ½” to 2″. And, resin types can be varied to meet your corrosion and fire resistant needs. For standard trench drain applications, polyester resins are most often used. The open area for the mesh grating is approximately 70%. Fiberglass Mesh grating is now available in 4′ or 8′ kits, which include grates, locking devices and frame rails. Custom lengths are also available upon request.

High Load Capacity (HLC)

High load capacity molded grating is commonly used in applications where heavy loads (such as fork truck traffic) are encountered in corrosive environments and in areas where cast iron grates are prone to theft, as they have no metal scrap value. High Load Class mesh grating is now available in 4′ or 8′ kits, which include grates, locking devices and frame rails. Multiple kits can be interconnected for longer runs to suit your application. Custom lengths are also available upon request. HLC mesh is made with high strength vinyl ester resins and come in 1.5″ and 2″ thicknesses. Non-slip surface coatings are also available. The grate has an open area of 48%.

Locking Devices

For all fiberglass grating, a special locking mechanism is required to keep it secure in the trench drain channel. These hold downs are often made of stainless steel. In most cases it works by strapping the cross-members of the grate to a center toggle attached to the channel. Attachment to the cross member keeps the locking device below the surface of the grate and out of the way of traffic above. Each fiberglass grate has its designated locking device depending on the mesh dimensions specified.

When corrosion resistance becomes the most important design criteria, the materials of choice are stainless steel, high density polyethylene and fiberglass. Thereafter, the cost and specific details of the application will dictate which material is best to specify.

Whether you need a large open area for fast draining or tight grate openings for ADA surfaces, Trench Drain Systems offers custom fiberglass products for your drainage application. Fiberglass grating can be molded into large sheets for later fabrication into smaller, custom shapes.

Trench Drain Systems is one of the largest distributors in the United States who are committed to providing you with quick solutions to all your surface water runoff problems. Our professional staff can assess your project requirements and quickly offer you competitive pricing and information regarding the products you need. DIY Fiberglass kits are now available and in stock. Contact us for a quote or Shop our online store today!

Phone: 610-882-3630

Email: Shop@TrenchDrain.com

Click here for a fast and free quote!